CUSTOM PRODUCTS

Isolofoam meets your needs.

Customized products and components. Manufacturing packaging solutions.

OUR SOLUTIONS

Whether protecting, filling a void, reinforcing, insulating or even sometimes ensuring the buoyancy of goods, our experts will put their sense of innovation to work to create the solution that meets your specific needs.

Multitude of sectors served

Manufacturer | Construction | Windows & Doors | Prefab Walls and Houses

Horticulture | Transport & Storage | Fishing | Commerce | Furnishings | Event Management

Applications

Custom Made

Product

Packaging

Support &

Handling

Lettering

Prefabricated

Walls

Protection

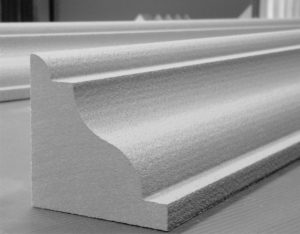

Architectural

Elements

Scenery

Manufacturing Process

Optimized for

your productivity.

Simple or complex products.

Short-, medium- or long-term series production.

Our experienced team will use its creativity and expertise to optimize a solution that integrates easily into your production chain and meets your needs.

- Custom cutting.

- Bonding and lamination of other materials such as cardboard, wood, coroplast and other membranes.

- Moulding and custom-mold design.

MATERIAL USED

- Expanded polystyrene (EPS)

- Neopor (Graphite enhanced EPS (GPS))

- Extruded polyethylene (EPE)

- Extruded polyethylene SFT (EPE)

Development Process

Technical support is vital to your project.

With Isolofoam, the development of custom-made products follows a step-by-step procedure, where nothing is left to chance.

Thorough.

Accurate.

Four steps.

- Needs analysis

Our incomparable technical service team will identify your specific needs. - From conception to prototypes and technical tests

Prototypes can be produced using existing parts and/or computer files. - Training support

If needed, clear instructions for assembly, packaging or other details are included to help inform your personnel. - Delivering on time and on budget

Our logistics and production capacity ensures that deadlines and budgets are respected.

LET US HELP CREATE

the best solution for you

Productivity | Quality | Savings

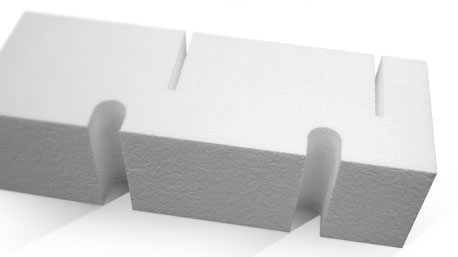

WELL-INSULATED

PREFAB WALLS AND HOUSES

The Isolofoam Group’s complete range of expanded polystyrene thermal insulation solutions is a smart choice for manufacturers of factory-built wall, housing components and homes.

Insulation panel | Wall components | Custom made

Providing significant cost savings

- High-performance and durable insulation, energy-efficient construction.

- Available in a variety of sizes according to your plans and specifications.

- Cut according to your specific needs. Minimizes material losses.

- Allows for quick and easy construction.

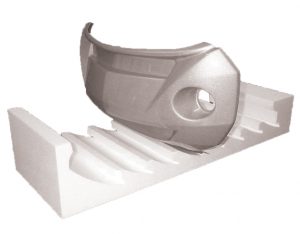

CUSTOM MADE PRODUCTS

AND PACKAGING

We design lightweight packaging and components that perfectly protect your products and facilitate handling and transportation. We only use materials with properties designed for packaging and transport.

Support | Case | Corner | U-shaped | Custom made

A win-win scenario

- Optimize your transport cost – Lightweight materials help maximize the value of the load.

- Excellent protective capacity – Less breakage.

- Easy handling of merchandise – Reusable packaging.

- Limited storage space – Optimize and customize your design.

EPS: A profitable choice

Packaging has a big impact on your profitability on many levels. Beyond the cost of packaging, other elements should be considered in defining your best solution in terms of productivity, savings and quality.

Effective protection

Expanded polystyrene has all the properties you want for a package component. It protects better than cardboard from repeated impacts and vibrations. It is also very durable, insulating, lightweight and reusable.

A sustainable material

The life cycle and properties of expanded polystyrene make it significantly more reusable than paper and cardboard. Its manufacture requires less energy, releases fewer pollutants into the air and is less contaminating to water and soil.

Sustainable Development

Recycling program

What happens to the majority of the polystyrene waste generated by our production process? We use them to make more products! You can help further reduce our environmental footprint by taking advantage of our pick-up service.

Expanded polystyrene: A green choice

Designed to optimize energy and materials, expanded polystyrene has tremendous eco-responsible properties. Its manufacture does not require chemicals, HFCs or HCFCs. It is 100% recyclable and reusable.