ISORAD V2 | R10-R15

Rigid radiant heating floor insulation - Under slab

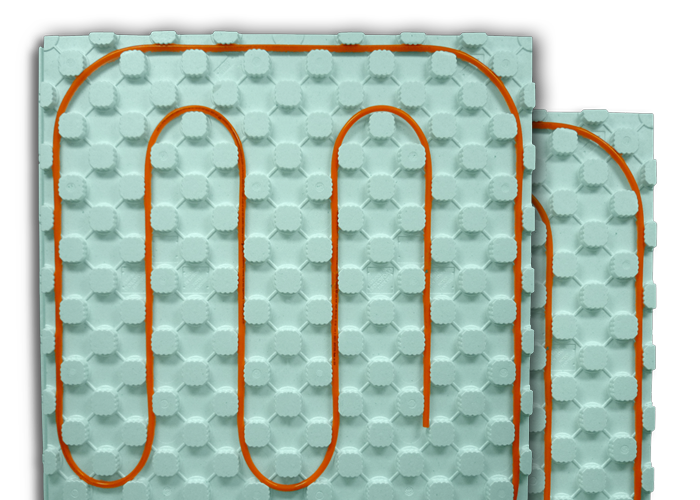

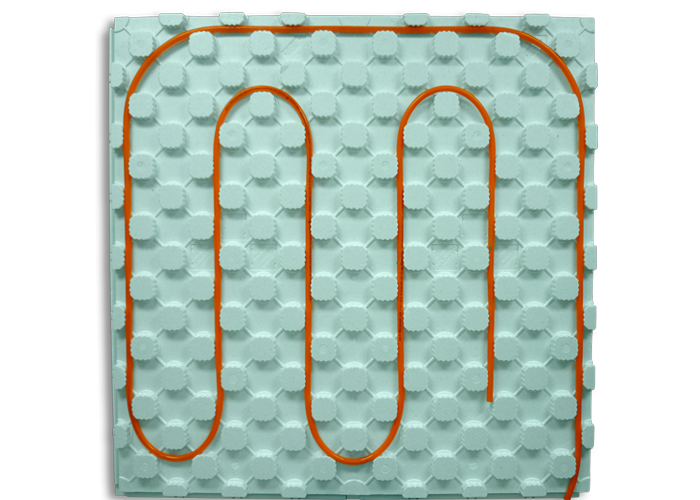

WITH MULTIDIRECTIONAL TUBE-RETENTION SYSTEM

By combining the insulation performance of an expanded polystyrene board with a multidirectional tube-retention system, ISORAD V2 provides the perfect solution for under slab insulation when embedding a radiant heating system in concrete. It can also be used for terrace and exterior slabs/ sidewalks/ parking lots to accelerate melting of ice and snow.

NEW CONSTRUCTION

Residential. Commercial. Industrial. Institutional. Agricultural.

Advantages

ELIMINATES HEAT LOSS

Efficient thermal barrier. ISORAD V2 prevents heat loss through the soil, maximizing the efficiency of the hot-water or glycol radiant heating system in the home and garage.

SECURED AND RESISTANT PANELS

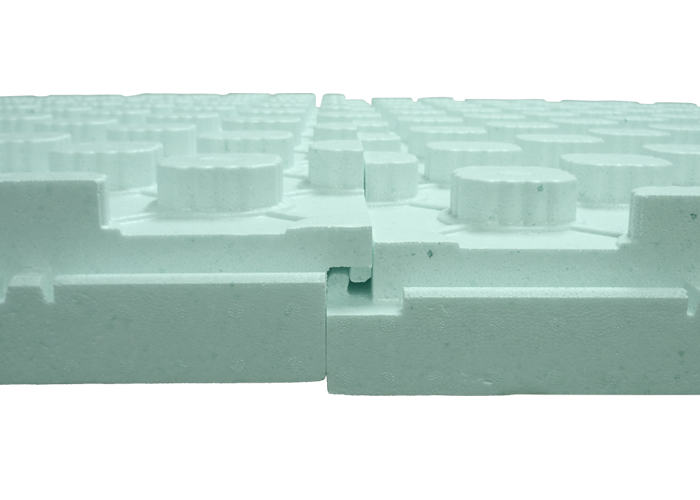

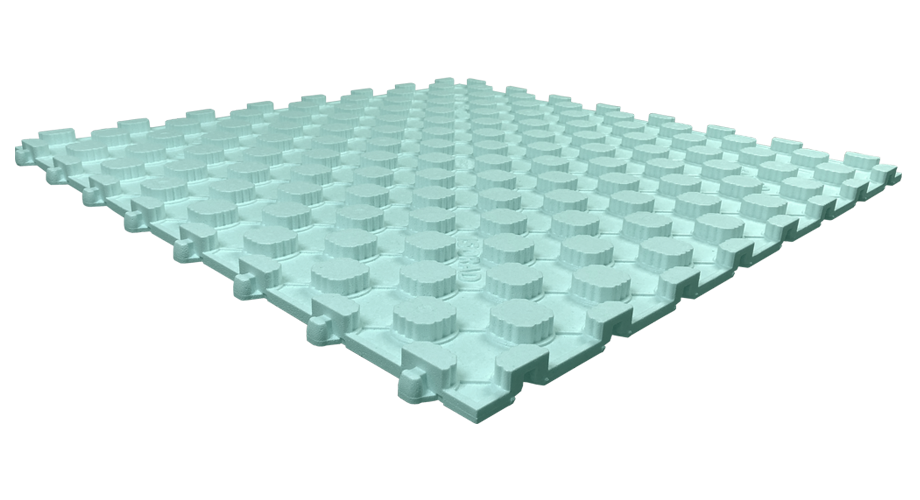

High-density clipping panels. The efficient, four-sided, ISOCLICK ALIGN interlocking system ensures pucks alignment and tubing retention, as well as easy and fast panels installation.

IDEAL TO DELINEATE HEATING ZONES

Multidirectional tube-retention system. Positioning tubing with ISORAD V2 panels is a simple task. The elevated pucks keep the tubes in place at regular intervals, while also allowing them to be oriented in multiple directions.

INSTALLATION: MORE EFFICIENCY

Speed and efficiency on the job site. By combining the insulation performance of an expanded polystyrene board with a multidirectional tube-retention system, the step of fixing the tubes to a wire mesh is eliminated. Makes the insulation and hot-water/glycol heating system installation easier and faster.

Efficient thermal barrier

- Ensures continuous and uniform insulation under the concrete slab.

- Increases comfort and energy efficiency.

- Stable and permanent insulation value.

- Generates energy savings year after year.

High-density clipping panels

- The ISOCLICK ALIGN 4-sided clipping system prevents panels from shifting and the appearance of non-insulated gaps.

- Holds up to foot traffic when installing the tubing.

- Different compressive strengths available.

- Lightweight, easy and fast to install panels, assisted by ‘start’ arrow and integrated cutting lines.

- Resistant to freezing, thawing, water and humidity.

Multidirectional tube-retention system

- Excellent retention of 1/2″ or 5/8″ diameter tubing.

- Ensures regular interval between tubes.

- Allows to respect the plans and easily realize heating zones according to design.

- The step of fixing the tubes to a wire mesh is eliminated.

- Less physically demanding and easy to install by one person.

Speed and efficiency on the job site

- Tubing easy to insert between the pucks—just walk it in!

- Eliminates the costs and effort of installing wire mesh and/or attaching tubing when slab reinforcement is not required.

- Reduces the number of steps and components required for a hydronic radiant floor system installation.

- Optimizes working time and labour costs.

THE PERFECT SOLUTION FOR RADIANT SLAB INSULATION

Reduces the number of components and steps required to install the system.

Optimizes labour time and costs.

Compliance & Certifications

ISORAD V2 allows you to easily meet building code and construction requirements for energy-efficient standards, such as Energy Star and Passive House.

- Registered industrial design

- CAN/ULC-S701 – Type 2, Type 3

- CCMC # 12895-L: Compliant to ULC-S701.1:17, EPS type 2 (ISORAD V2 160)

- CCMC # 13638-L: Compliant to ULC-S701-11, EPS type 3 (ISORAD V2 250, ISORAD V2 300)

- CAN/CSA‐B214, Installation Code for Hydronic Heating Systems, R-value required

- Certified low-chemical-emission product:

GREENGUARD – UL 2818, GREENGUARD Gold – UL 2818

Can contribute to obtain LEED credits.

Compliance Certification is available upon request

Installation

ISORAD V2 product is quick and easy to install.

To ensure maximum insulating performance, make sure the installation follows the recommended practices.

Using ISORAD V2 requires the installation of insulation and tubing prior to pouring the concrete required to cover the heating system.

*Videos are for information purposes only. Refer to the installation recommendations and effective requirements in your area before any work starts.

- Soil preparation: Level crushed granular base or sand.

- Install a vapour barrier polythene over the entire surface (if specified in the building code in your area) to ensure airtightness, moisture protection and soil gas control.

- Install the panels over the entire surface to be insulated.

- Start the installation by positioning the ‘start’ arrow at the corner of the wall to ensure the panels are properly interlocked.

- To start a new row using the excess of a panel and to ensure alignment of the tube-retaining pucks, use the cutting lines on the back.

- Following the designed laying pattern defined by the heating system professional, secure the tubing between the pucks by walking over it.

- The elevated puck system allows for the installation of 1/2″ or 5/8″ diameter tubing, with tubing able to be spaced at multiples of 3″.

- The spacing between the tubes must be defined by the heating system professional and according to the needs of the building to ensure its proper performance.

- If necessary, use tubing fasteners to hold the tubes in tighter bends or at the outlet for connection to the heating system.

- Install wire mesh if required for slab reinforcement.

- Pour the concrete slab.

- A minimum of 3″ of concrete above the pucks is recommended. Refer to the applicable code requirements of the type of building to determine required thickness according to the application loads.

- The tubes must be completely embedded in the concrete.

Tips and Tricks

To make the tubing turn easier, push or pull it so that it’s in constant contact with the pucks.

SUSTAINABLE BUILDING

LONG-TERM PERFORMANCE

- Stable insulation value year after year.

- Hydronic radiant heating provides increased comfort and energy savings.

Technical specifications

- 48″ x 48″ panels

- Allows insertion of 1/2″ or 5/8″ internal diameter tubing*

- ISOCLICK ALIGN 4-sides

- Compressive strength of 16 psi (110 kPa), 25 psi (173 kPa) or 30 psi (210 kPa)

| Thickness | ISORAD V2 160 R Value (RSI) |

ISORAD V2 250 R Value (RSI) |

ISORAD V2 300 R Value (RSI) |

| 2 1/2″ (overall 3 1/2″) |

R10.1 (RSI 1.77) | R10.5 (RSI 1.85) | R10.6 (RSI 1.87) |

| 3 3/4″ (overall 4 3/4″) |

R15.1 (RSI 2.66) | R15.7 (RSI 2.76) | R15.9 (RSI 2.80) |

*Tube 1/2″: Ø int. 1/2″, Ø ext. 5/8″

*Tube 5/8″: Ø int. 5/8″, Ø ext. 3/4″

Also available on request:

- Dimensions of 24″ x 48″

Residential. Multi-units. Condominiums. Office buildings.

ISORAD V2 available in a thin version for storey floors

Everything you need to facilitate the installation of hydronic radiant flooring on upper storey floors and ensure optimal system performance! ISORAD V2 in its thin version is also suitable for renovation projects on an existing slab.

Environmentally

Friendly

Isolofoam expanded polystyrene insulation products are eco-responsible.

- 95-98% air, 2-5% plastics

- Do not contain HFCs nor HBCDs that damage the ozone layer

- Contain recycled material

- Recyclable and reusable

- Greenguard- and Greenguard Gold-certified products