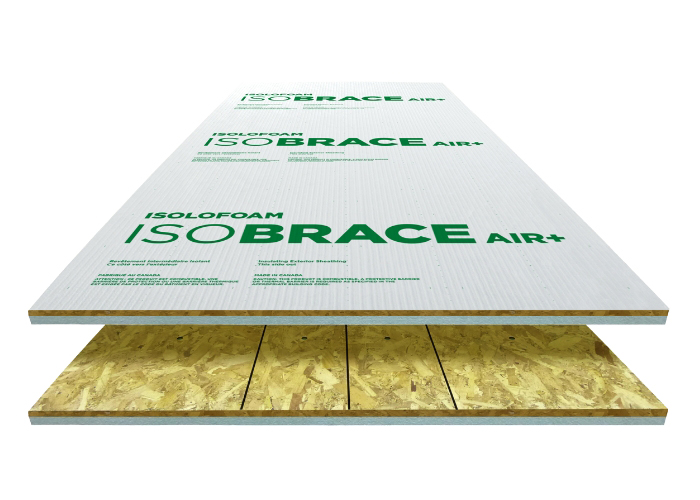

ISOBRACE OSB and ISOBRACE AIR+

Rigid insulation for above grade exterior walls

LAMINATED TO A 7/16″ OSB

ISOBRACE panels combine the insulating performance of expanded polystyrene panels and the rigidity of 7/16″ oriented strand board (OSB). They ensure continuous insulation while helping to increase the structural rigidity of the building. The integrated membrane of ISOBRACE AIR+ provides a continuous and resistant air and weather barrier.

NEW AND RENOVATION

Residential. Commercial.

Advantages

An expanded polystyrene panel laminated to an OSB panel perforated at regular intervals.

The combination of ISOBRACE OSB and a membrane made of strong non-woven engineered fabrics laminated onto the OSB surface, which can be used as a weather and an air barrier.

#avantage {display: none;}

Advantages

Continuous insulation envelope

-

Eliminate thermal bridging between the structure and the exterior cladding.

-

Completely insulate floor joists – with 9′ length.

-

Meet the highest insulation requirements.

-

Stable and permanent insulating value.

Increased structural rigidity

-

Contribute to increase the structural strength of the building’s walls.

-

Can eliminate the need to add temporary bracing.

-

Provide support for exterior cladding (when in accordance with cladding manufacturer’s recommendations).

Water vapour permeability

- OSB panel perforated at regular intervals to increase water vapour permeability.

Ease of installation

-

All-in-one products eliminating multiple installations.

-

Compatible with different types of building structures.

-

Reduce working time and labour costs.

![]()

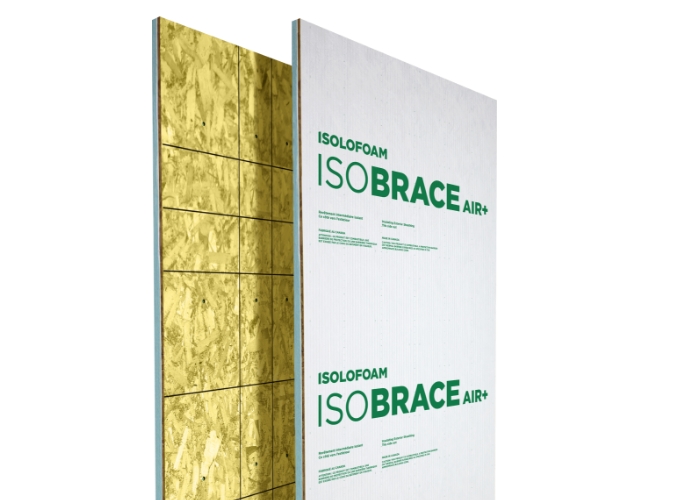

Get more with ISOBRACE AIR+

Continuous air and water-resistive barrier

-

No need to add another membrane when panels are sealed.

-

Creates a continuous air barrier.

-

Flashing easy to install simply by lifting the air barrier membrane.

-

Various compatible sealing tapes and self-adhesive sealing membranes.

When properly installed and sealed, ISOBRACE AIR+ panels can serve as an air barrier, a weather barrier, and continuous insulation at the same time. A single product to install!

Compliance & Certifications

ISOBRACE OSB and ISOBRACE AIR+ panels allow you to easily meet building code requirements and the highest energy-efficient construction standards, such as ENERGY STAR.

Expanded polystyrene insulation (EPS)

- CAN/ULC-S701 – Type 2

- CCMC #12895-L: Compliant to ULC-S701.1:17, EPS type 2

- Product certified for low chemical emissions: GREENGUARD – UL 2818, GREENGUARD Gold – UL 2818

OSB panel

- CSA-0325 – W24, Exposure 1

- DOC PS-2

- The oriented strand boards (OSB) used in the composition of ISOBRACE OSB and ISOBRACE AIR+ are FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) certified.

Membrane ISOBRACE AIR+

- CCMC #13426-R: Sheathing membrane

- CCMC #13617-R: Air barrier material

Can contribute to obtain LEED credits.

Compliance certification available upon request

Installation

ISOBRACE OSB and ISOBRACE AIR+ products are quick and easy to install.

To ensure maximum insulating performance, make sure the installation process follows recommended practices.

Refer to the ISOBRACE AIR+ Installation Guide for complete installation instructions.

- Install panels with OSB and/or printed membrane facing outward, allowing the foam to be in direct contact with the framing. Ensure that all edges of the panel are well supported.

- New construction: If installed in a seismically active area, validate bracing requirements that apply.

- Fasten panels with common, twisted, or ring nails.

- 6″ o/c at the edge of the panel

- 12″ o/c along intermediate supports

- When installing ISOBRACE OSB, cover the product with an air/weather barrier membrane.

- When using ISOBRACE AIR+, seal all joints with sealing tape or a self-adhesive sealing membrane. Framing nails used for fixing the panel must be covered.

- Seal surface changes with a sealant (openings, electrical outlets, etc.) and prepare the outline of the windows for airtightness and watertightness.

- Install 1″ x 3″ wood furrings vertically or diagonally (if recommended by the siding manufacturer).

- Install the exterior finish.

Technical specifications

- 48″ x 96″ or 48″ x 108″ panels

- Butt/square edge

| Thickness | R Value (RSI) |

| 1 5/16″ | R4.15 (RSI 0.73) |

| 1 9/16″ | R5.15 (RSI 0.91) |

| 1 13/16″ | R6.18 (RSI 1.08) |

| 2 3/16″ | R7.65 (RSI 1.35) |

Also available on request:

- Other thicknesses

Environmentally

Friendly

Isolofoam expanded polystyrene insulation products are eco-responsible.

- 95-98% air, 2-5% plastics

- Do not contain HFCs nor HBCDs that damage the ozone layer

- Contain recycled material

- Recyclable and reusable

- Greenguard- and Greenguard Gold-certified products