ISORAD unidirectional

Rigid radiant heating floor insulation - Under slab, large area

WITH ELEVATED GROOVES

ISORAD offers the optimal solution for under-slab insulation and large-diameter tube retention for large-area projects where a radiant heating system is embedded in concrete. It can also be installed beneath outdoor terraces, sidewalks and parking lots to accelerate the melting of ice and snow.

NEW CONSTRUCTION

Commercial. Industrial. Institutional. Agricultural.

Advantages

ELIMINATES HEAT LOSS

Efficient thermal barrier. ISORAD prevents heat loss through the soil, offers a stable insulation performance and maximizes a building’s energy efficiency.

IDEAL FOR LARGE SURFACES

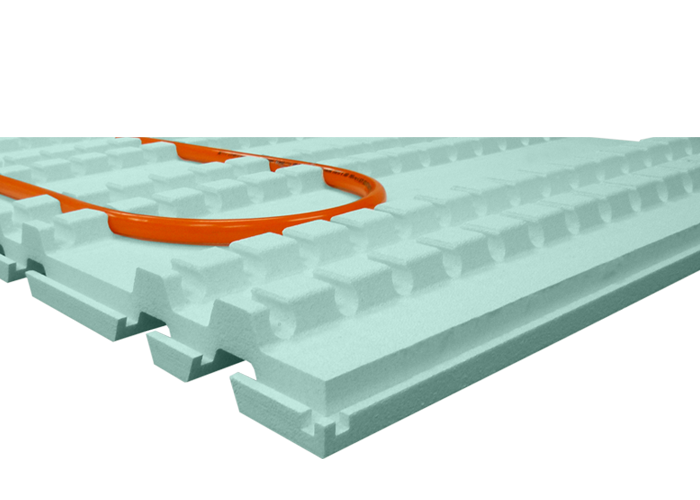

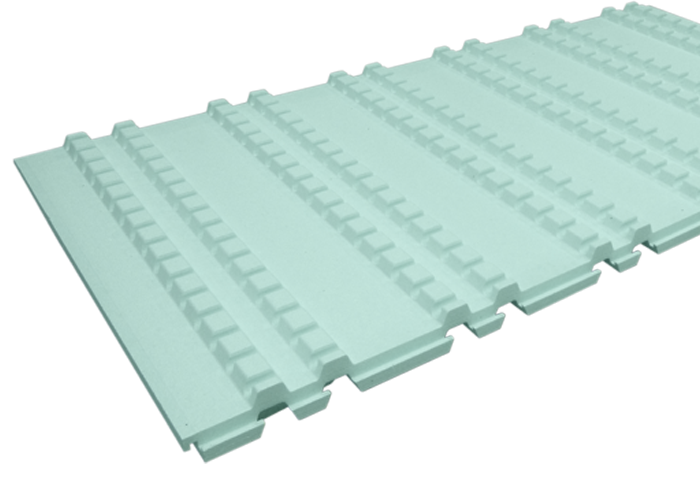

Efficient elevated grooves. Makes the installation of large-diameter tubing easier in a hot water or glycol large-floor heating system.

RESISTANCE AND DURABILITY

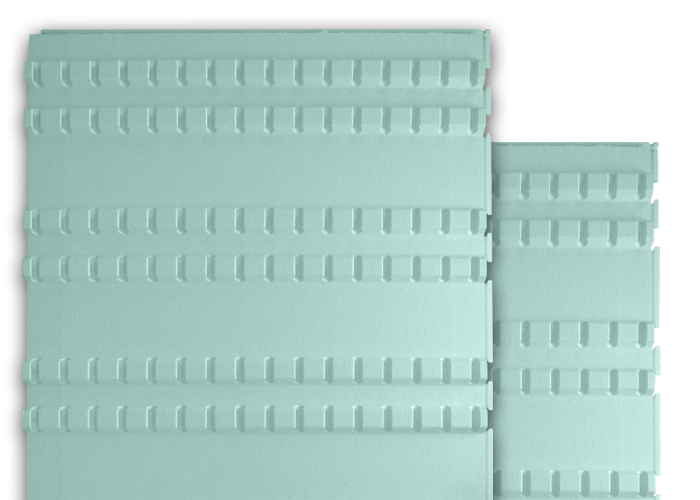

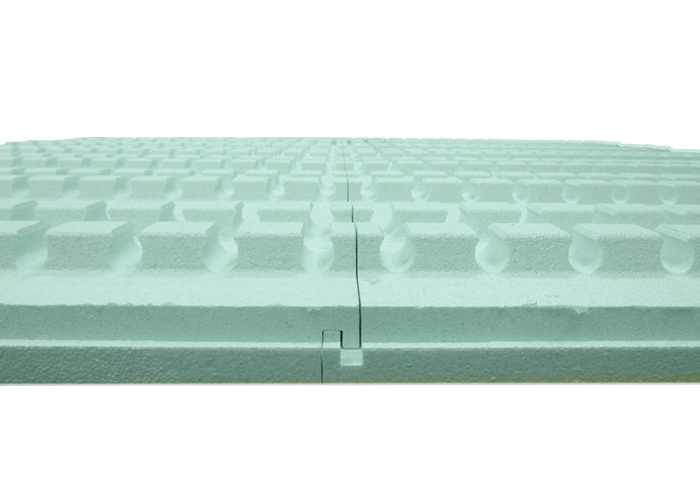

High density interlocking panels. Thanks to ISORAD’s high density and 4-sided interlocking system, jobsite breakage is reduced and the panels stay in place during installation.

INSTALLATION: MORE EFFICIENCY

Reduce your labour costs. By combining a rigid insulation panel and a tube-retention system in a single product, the need to attach tubes to wire mesh is eliminated. That makes the installation of both the insulation and radiant floor system easier and faster.

Efficient thermal barrier

- Ensures continuous and uniform insulation under the concrete slab.

- Increases comfort and energy efficiency.

- Generates energy savings year after year.

- Stable and permanent insulation value.

Efficient elevated grooves

- Excellent retention of 3/4″ or 1″ diameter tubing.

- Unidirectional installation and regular interval between the tubes.

- Tubing is easy to insert between grooves by walking them in.

High density interlocking panels

- Offered in high density to meet requirements of large commercial, industrial, institutional or agricultural buildings.

- Stands up to repeated foot traffic during installation.

Reduce your labour costs

- Large-format panels expedite insulation installation.

- Elevated grooves facilitate the linear installation of large-diameter tubing.

- It reduces the number of components and steps required to install the system.

Compliance & Certifications

ISORAD allows you to easily meet building code and construction requirements for energy-efficient construction standards, such as Energy Star and Passive House.

- CAN/ULC-S701 – Type 2, Type 3

- CCMC # 12895-L: Compliant to ULC-S701.1:17, EPS type 2 (ISORAD 200)

- CCMC # 13638-L: Compliant to ULC-S701-11, EPS type 3 (ISORAD 300)

- CAN/CSA‐B214, Installation Code for Hydronic Heating Systems, R-value required

- Certified low-chemical-emission product:

GREENGUARD – UL 2818, GREENGUARD Gold – UL 2818

Can contribute to obtain LEED credits.

Compliance Certification is available upon request

Installation

ISORAD product is quick and easy to install.

To ensure maximum insulating performance, follow the recommended installation practices.

Installing ISORAD requires the installation of insulation and tubing prior to pouring concrete, which must cover the heating system.

Refer to the applicable building code requirements and targeted energy performance to determine the insulation value of the selected product.

- Soil preparation: Level crushed granular base or sand, panels must have a solid base and be well supported.

- Install a vapour barrier polythene over the entire surface (if specified in the building code in your area) to ensure airtightness, moisture protection and soil gas control.

- Install the insulation panels over the entire surface to be insulated.

- Insert the tubing by walking on it to secure it between the grooves.

- The elevated groove system allows for the installation of 3/4″ or 1″ diameter tubing and a spacing of the tubing at multiples of 3″.

- The spacing between the tubes must be defined by the heating system professional and according to the needs of the building to ensure its performance.

- If necessary, use tubing fasteners to secure the tubes when needed.

- Install wire mesh if required for slab reinforcement.

- Pour the concrete slab.

- A minimum of 3″ of concrete above the elevated grooves is recommended. Refer to the applicable code requirements of the type of building and determine the required thickness according to the application loads.

- The tubes must be completely embedded in the concrete.

SUSTAINABLE BUILDING

LONG-TERM PERFORMANCE

- Stable insulation value year after year.

- Increased comfort and energy saving thanks to the hydronic radiant heating.

Technical specifications

- 48″ x 96″ panels

- Elevated grooves for tubes of 3/4″ or 1″ internal diameter

- Interlocking system on 4 sides

- Compressive strength of 20 psi (140 kPa) or 30 psi (210 kPa)

| Thickness | Tubes* | ISORAD 200 R Value (RSI) |

ISORAD 300 R Value (RSI) |

| 1 13/16″ (overall 3 1/16″) |

3/4″

1″ |

R7.6 (RSI 1.34) | R7.7 (RSI 1.35) |

| 2 7/16″ (overall 3 11/16″) |

3/4″

1″ |

R10.2 (RSI 1.8) | R10.3 (RSI 1.82) |

*Tube 3/4″: Ø int. 3/4″, Ø ext. 7/8″

*Tube 1″: Ø int. 1″, Ø ext. 1 1/8″

Also available on request:

- Dimensions of 48″ x 48″

- Other thicknesses

- Other densities

Environmentally

Friendly

Isolofoam expanded polystyrene insulation products are eco-responsible.

- 95-98% air, 2-5% plastics

- Do not contain HFCs nor HBCDs that damage the ozone layer

- Contain recycled material

- Recyclable and reusable

- Greenguard- and Greenguard Gold-certified products